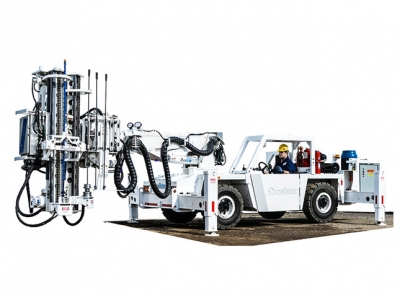

DynaBolter V2.0 - Roof Bolter

Description

Technical Specifications

Safety

- Warning indicator lights and gauges

- Back-up alarm

- ROPS/FOPS certified canopy

- Low mount amber strobe light

- Ansul check fire suppression and control system

- Fire extinguisher

- SAHR (spring applied, hydraulically release) parking brake

- Hydraulics cut-out with machine in gear

- All functions automatically disable with door open

- No hydraulic lines in cab

- Dust suppression collection system (optional)

Controls

- Dual joysticks with thumb rockers control: outriggers, boom, head, drill and bolt functions

- Electro-hydraulic control

- Inclinometer

Working Capacity

- Boom Swing: 21 degrees left/21 degrees right

- Install 1829mm (6’-0”) bolts in a 2286mm (7’-6”) back

- Capable of multiple bolt diameters

- Adaptable to shell or epoxy style bolts

- Uses 8-bolt carousel

- Maximum back height: 4890mm (192.5")

- Minimum back height: 2032mm (80.0")

- Maximum forward reach: 4674mm (184.0")

Chassis

- Overall height: 1905mm (75.0”)

- Overall length: 8382mm (330.0”)

- Overall width: 2210mm (87.0”)

- Ground clearance: 279mm (11.0”)

- Wheelbase: 2438mm (96.0”)

Engine

- 100 HP turbocharged diesel

- Meets Tier IV emissions standards

- Engine protection shut-down system

- Neutral safety start

Transmission and Drivetrain

- Power-shift automatic transmission

- 3 mode hydraulic steering

- Four wheel drive

- Torque converter transmission

- F-N-R selector mounted on steering wheel

- High load capacity drive and steer axles

- Limited slip differential

- Four-wheel, hydraulic power steering

- Inner turning radius: 12'

Operator’s Cab

- Single operator—sit down

- 177mm (7.0”) onboard LCD operation screen

- Forward and rear facing cameras standard, 360 degree view camera optional

Work Lights

- Front and rear LED work lights

- LED remote operated spotlight (optional)

- Extra fender mounted work lights

Drill Options

- Hydraulic rotary

- Hydraulic percussion drifter

Automated Epoxy Injection (Optional)

- Epoxy injection controlled from operator's cab

- Injects epoxy using hydraulically driven compressed air

- Separate arm switch and fire button prevents accidental discharge of epoxy

- Smart check system ensures all conditions are met before firing epoxy

Electric Power Pack (Optional)

- 600 volt for drilling and bolting functions

Downloads

| File Name |

Type |

|

|

PDF |

Download |